How to choose Infrared material

There are three simple points to consider when choosing the right IR material. While the selection process is simpler because the practical selection of materials for infrared light will be much smaller compared to visible light, these materials will generally be more expensive based on reasons such as manufacturing and material cost.

1. Thermal Properties – Optical materials are often placed in environments where temperature changes. In addition, a common concern is that IR applications often generate large amounts of heat. The material should be evaluated for its refractive index gradient and coefficient of thermal expansion (CTE) to ensure that it provides the required properties to satisfy the user. CTE is the rate at which a material expands or contracts when its temperature changes. For example, Germanium materials have very high refractive index gradients, which may degrade optical performance if used in thermally unstable environments.

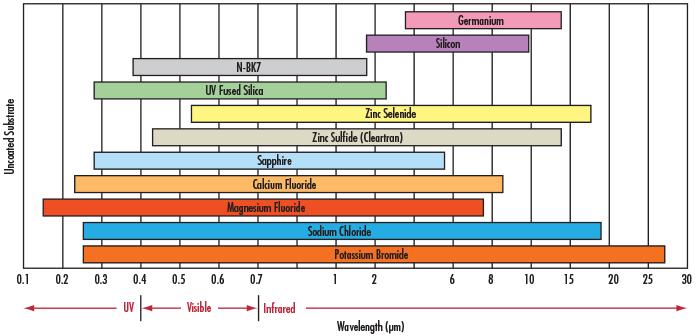

2. Transmission – Different applications can operate in different IR spectral regions. Depending on the wavelength used, some IR substrates perform better (Figure 1). For example, if the system will operate in the MWIR region, germanium is more ideal than sapphire, which is more suitable for the NIR region.

3. Refractive Index – IR materials vary much more in their refractive index than visible materials and are therefore more flexible in system design and allow for more variation. Unlike visible materials, such as N-BK7, which are suitable for the entire visible light spectrum, IR materials are generally only suitable for narrow, small frequency bands within the IR spectrum, especially when AR coatings are applied.

Figure 1: Comparison of Infrared substrates (The wavelength range applicable to N-BK7 is also applicable to most substrates such as B270, N-SF11, BOROFLOAT®, etc. used in visible wavelengths)

While many IR materials exist, only a small fraction of them are primarily used by the optics, imaging, and optoelectronics industries to make off-the-shelf components. Calcium fluoride, fused silica, germanium materials, Magnesium fluoride, N-BK7, potassium bromide, sapphire, silicon, sodium chloride, zinc selenide and zinc sulfide have their own unique properties that make these materials not only differentiated from each other and also make them suitable for specific applications. The following table provides a comparison of some commonly used substrates.

IR Material Properties

|

Name |

efractive Index (nd) |

Dispersion Coefficient (vd) |

density (g/cm3) |

CTE (x10-6/°C) |

dn/dT |

Knoop Hard Spend |

| 1.434 | 95.1 | 3.18 | 18.85 | -10.6 | 158.3 | |

|

Fused Silica (FS) |

1.458 | 67.7 | 2.2 | 0.55 | 11.9 | 500 |

| 4.003 | N/A | 5.33 | 6.1 | 396 | 780 | |

| 1.413 | 106.2 | 3.18 | 13.7 | 1.7 | 415 | |

|

N-BK7 |

1.517 | 64.2 | 2.46 | 7.1 | 2.4 | 610 |

|

Potassium Bromide (KBr) |

1.527 | 33.6 | 2.75 | 43 | -40.8 | 7 |

| Sapphire | 1.768 | 72.2 | 3.97 | 5.3 | 13.1 | 2200 |

| 3.422 | N/A | 2.33 | 2.55 | 1.60 | 1150 | |

|

Sodium Chloride (NaCl) |

1.491 | 42.9 | 2.17 | 44 | -40.8 | 18.2 |

| 2.403 | N/A | 5.27 | 7.1 | 61 | 120 | |

|

Zinc Sulfide (ZnS) |

2.631 | N/A | 5.27 | 7.6 | 38.7 | 120 |

IR material comparison

| Name |

Properties / Typical Applications |

|

Calcium Fluoride (CaF2) |

Low absorption; high refractive index uniformity For spectroscopy, semiconductor processing and cooling thermal imaging |

|

Fused Silica (FS) |

Low CTE and excellent transmission in IR For interferometry, laser instrumentation, spectroscopy |

|

Germanium (Ge) |

High index of refraction; high Knoop hardness; excellent transmission in the mid-wave to long-wave infrared range IR imaging for thermal imaging, harsh environments |

|

Magnesium Fluoride (MgF2) |

Wide transmission range; resistant to high-energy radiation For windows, lenses and polarizers that do not require AR coating |

|

N-BK7 |

Low-cost material for visible light and NIR applications For machine vision, microscopy, industrial applications |

|

Potassium Bromide (KBr) |

Mechanical shock resistance; water soluble; wide transmission range for FTIR spectroscopy |

|

Sapphire |

Very durable with good transmission in IR For IR laser systems, spectroscopy and harsh environment equipment |

|

Silicon (Si) |

For spectroscopy, MWIR laser systems, THz imaging |

|

Sodium Chloride (NaCl) |

Water soluble, low cost, excellent transmittance from 250nm to 16µm, sensitive to thermal shock for FTIR spectroscopy |

|

|

Low absorption; thermal shock resistance CO2 Laser Systems and Thermal Imaging |

|

Zinc Sulfide (ZnS) |

Superior transmission in the visible and IR range, stiffer and more chemically resistant than ZnSe for thermal imaging |